What is an Obsolete Bearing?

An obsolete bearing is a bearing no longer made by a manufacturer and thus considered "obsolete."

A growing concern for many organizations is finding and sourcing suppliers of discontinued or obsolete mechanical components such as bearings.

Many bearing manufacturers in the United States have manufactured more than 120,000 bearing types. At the same time, companies have discontinued producing numerous bearings and a variety of slow-moving lines due to a reduction in the range of bearing sizes available today.

We have a wide selection of bearings; including new, discontinued, and hard-to-find brands:

- Timken

- FAG

- Koyo

- SKF

- Dodge

- NDH Bearing/Delco

- Shafer

- MPB/Andrews Bearing Corp

- Hoover NSK

- Killian

- Orange

- Norma-Hoffman

- Federal-Mogul

- And more...

Problems with locating that hard-to-find bearing

We know how frustrating it is to locate hard-to-find bearings that could force you to go outside your standard supply chain, especially if they are discontinued or no longer supported by the manufacturer.

Additionally, many manufacturers require minimum order quantities that may not fit your needs.

Do you wish you could have hassle-free ordering without a minimum order quantity?

Have you struggled to find a company to manufacture obsolete bearings?

Is USA with US steel important to you?

Our bearing manufacturing services enable you to get the bearing you need according to your order requirements.

We specialize in manufacturing ball and cylindrical roller bearings, but our capabilities don’t stop there.

- 100% USA Steel

- 100% Made In USA

- Meets or Exceeds Manufactures Requirements

Are you trying to update your old bearing?

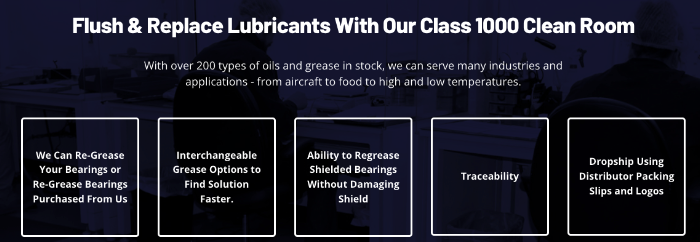

We carry over 200 types of grease and oil in stock from all the top companies, including:

- Mobil

- Chevron

- NYE Lubricants

- Aeroshell

- Castrol

- Krytox

- And more....

Grease remains in place, doesn't leak out easily, improves sealing, and does not require monitoring. It requires more labor to clean out and replenish and is very expensive.

General grease (National Lubricating Grease Institute (NLGI #2) is the most common lubricant used in bearings. It is commonly used in motor applications.

Synthetic grease, used in aerospace applications, fits the parameters such as low torque requirements or low/high temperatures.

Grease lubrication features include reduced maintenance time, less leakage than oil, and confines itself to the housing or bearing.

We have a cleanroom onsite to bring grease up to date.

Major manufacturers trust our relubrication services, such as:

We can allow you to order any quantity, provide complete traceability, and guarantee the quality of workmanship.

Read more about Bearing Lubrication Tips & Mistakes You Might Be Making.

Conclusion

We understand that different applications call for other bearings and have found that specific discontinued bearings are some of the most demanded items.

At BDS, we can help you find those Obsolete Bearings you're looking for to help you reduce downtime and guarantee the quality you and your customers deserve.

Let us know what you need and talk to a bearing expert today to help you get started.