Imagine a bearing that provides value across production processes and entire operations. It identifies impending problems and then communicates them wirelessly.

The use of "smart" bearing technology is a joint effort between bearings and the Industrial Internet of Things (IIoT). They are called smart bearings.

Bearings that operate smoothly keep manufacturing processes moving. Bearings that adopt a proactive approach to maintenance by monitoring machine processes such as pressure, force, and vibration are smart.

At Bearing & Drive Systems, we're committed to providing global sourcing network solutions that help you find the authentic bearing & PT products that your customers need now.

Because we take extending your bearings' lives enormously, we put together this infographic to discuss smart bearings, what they are, and how they will change the way you do business.

IoT and the Smart Bearing...

Like it? Share it:

Is the Onset of Industry 4.0 Accelerating Innovations in the Bearing Market?

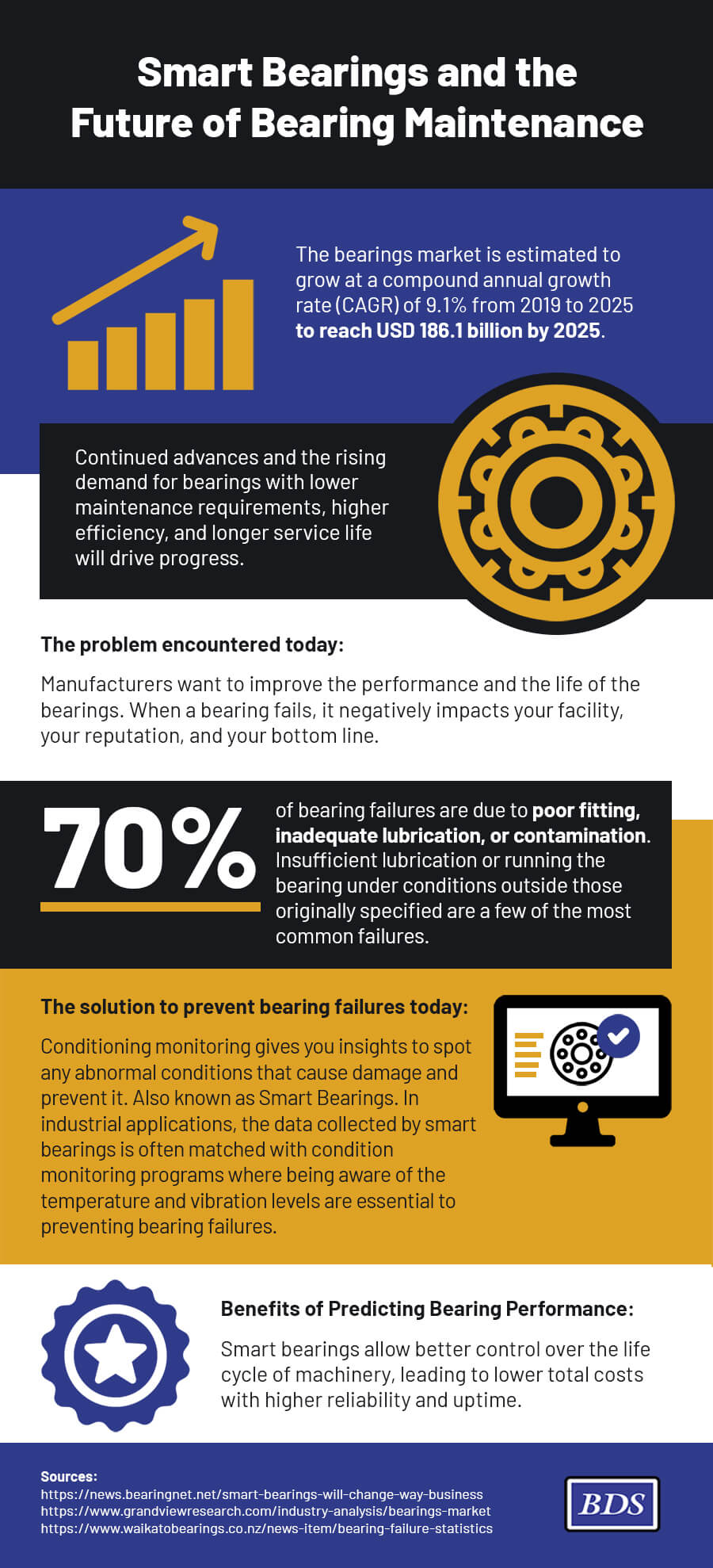

The bearings market is estimated to grow at a compound annual growth rate (CAGR) of 9.1% from 2019 to 2025 to reach USD 186.1 billion by 2025.

Continued advances and the rising demand for bearings with lower maintenance requirements, higher efficiency, and longer service life will drive progress.

Why?...

The problem encountered today:

Manufacturers want to improve the performance and the life of the bearings. When a bearing fails, it negatively impacts your facility, your reputation, and your bottom line.

The top causes of bearing failure today:

70% of bearing failures are due to poor fitting, inadequate lubrication, or contamination. Insufficient lubrication or running the bearing under conditions outside those originally specified are a few of the most common failures.

The solution to prevent bearing failures today:

Conditioning monitoring gives you insights to spot any abnormal conditions that cause damage and prevent it. Also known as Smart Bearings. In industrial applications, the data collected by smart bearings is often matched with condition monitoring programs where being aware of the temperature and vibration levels are essential to preventing bearing failures.

Benefits of Predicting Bearing Performance:

Smart bearings allow better control over the life cycle of machinery, leading to lower total costs with higher reliability and uptime.

The Bearings Market Estimated to Grow

The bearings market is estimated to grow at a compound annual growth rate (CAGR) of 9.1% from 2019 to 2025 to reach USD 186.1 billion by 2025. There has been a rising demand for bearings with lower maintenance requirements, higher efficiency, and longer service life.

The integration of IoT capabilities furthers manufacturers to monitor bearing operations constantly. The Industrial Internet of Things' onset has encouraged adoption and constant monitoring of connected equipment and machinery.

"Bearings used in various machinery need to be monitored continuously to ensure efficiency, reliability, consistency, and cost-effectiveness of the operations. Upcoming technologies, such as smart bearings, will help manufacturers monitor bearing operations constantly. This factor is expected to create new opportunities in the bearing market."

[source: Transparency Market Research - Bearing Market]

Smart Bearing Technology and Conditions Monitoring

Bearings are parts that help machinery to work smoothly and increases the efficiency of the machine. And the most crucial factor is the fitting of the bearing with the machine parts.

However,

The proper bearing analysis is the key to keeping equipment running efficiently, reliably, consistently, and cost-effectively.

Want to know the best part?

Smart bearings are instrumented with sensors to provide information about their surrounding environment, including:

- Speed

- Direction

- Temperature

- Vibration

- Load

- Levels of debris and other factors

The integration of sensors and bearings is what gives smart bearings their name.

"Smart bearing technology is used in a variety of industries, including automotive and industrial. Specific applications include, but are not limited to, automotive wheel speed and direction feedback, machine control, robotic control, printing industries, paper converting, web processing, wood processing, chemical production, textile, agriculture machinery, and food processing." [source: Smart Bearing Technology]

Conditions Monitoring

A monitoring system with sensor-enabled bearings will allow manufacturers to quickly understand the conditions and eliminate downtime associated with unexpected equipment failures.

How Smart Bearings Will Change the Way You Do Business and Enable Growth

Smart bearings adopt a proactive approach to maintenance by monitoring machine processes such as pressure, force, and vibration (each provides critical data for predictive maintenance).

In industrial applications, the data collected by smart bearings is often matched with condition monitoring programs where being aware of the temperature and vibration levels are essential to preventing bearing failures.

Digitalization is making a change in how maintenance is performed. Performance on real-time updates on the condition of bearings and other components allow for advanced diagnostics.

Adopting a proactive maintenance approach has many benefits.

When a piece of equipment malfunctions, the entire process comes to a standstill while the problem is fixed. By accessing advanced data on a machine's operating status, it’s possible to reduce downtime and prevent factors that cause breakdowns drastically.

Avoiding any machine breaks also minimizes the need for repairs during operating hours.

In Summary

Unforeseen operating conditions and improper maintenance can result in premature and sudden failure bringing an entire production to a halt.

Learning the causes behind a failure or before it happens can enable manufacturers to address the root of the problem more effectively. Bearings and IoT can work together to inform each other.

It's nearly impossible to imagine a world without bearings and the technology they make up.

Bearings have become an essential part of day-to-day life since their invention. Finding an original bearing and PT parts that you need shouldn't be a hassle.

At Bearing and Drive Systems, we know that the worry of providing inferior products to your customers is real, but it doesn't have to be.

Our global sourcing network solutions can help you find the authentic bearing and PT products you're looking for to help you reduce downtime and guarantee the quality you and your customers deserve.

Talk to one of our bearing experts today to tell us what you need, and we can help you get started.

featured image: Image by Gerd Altman from Pixabay